With customer demand for more environmentally friendly work on the rise, we take a look at some of the more green-minded printers that could help your wrapping business race ahead in a sustainable way.

No matter what area of the print, display, graphics or signage markets you are working in, the environment is now one of the most important factors to consider when it comes to producing work.

For those in the traditional print markets, this could be the type of paper they are printing on, the choice of ink or even the press they are using to produce the work, whereas in the digital signage sector, thoughts turn more towards energy usage and the impact of this on the environment.

In terms of vehicle wrapping, there are a number of key factors to consider when it comes to producing quality, yet green-minded, applications for customers. First, there is the film or vinyl you are working with, then the type of inks and also the printing hardware, with all of these having an impact on the final environmental impact of the project.

The primary challenge is ensuring you are working with material and technology that is not only kinder to the planet but does not negatively impact the final look of the wrap. After all, when it comes to vehicle wrapping, appearance is everything!

With this in mind, we have picked out some of the more green-minded solutions available in this competitive market, focusing on the types of printing hardware you can use to enhance your environmental credentials.

Fast and reliable solutions

Roland DG not only recognises the value of a quality print job on vehicle wraps, but also the valuing of ensuring the final printed piece is as environmentally friendly as possible. Mark Elvidge, senior product manager at Roland DG EMEA, says for this reason, investment in a quality, reliable printer is crucial.

Caption: Roland DG recommends its TrueVIS wide-format printer/cutters as effective, green print solutions for producing vehicle wraps.

Caption: Roland DG recommends its TrueVIS wide-format printer/cutters as effective, green print solutions for producing vehicle wraps.

“Print professionals looking to branch into vehicle wrapping should also ensure the machine they choose is fast and reliable,” Elvidge said. “If the vehicle being wrapped is off the road for longer than intended due to an inconsistent printer, it will cost customers significantly. For the same reason, it is also important to choose a print supplier which offers excellent support and timely repairs should a printer need fixing.

“Print professionals should look out for a machine that can deliver high quality applications for customers to develop strong customer satisfaction and loyalty. The printer should be able to offer a good range of media and laminate compatibility for versatile application offerings, as well as being efficient to increase output capacity.

“Before purchasing, print professionals should investigate ease of use, speed of outgassing time and the machine specific functions and software to streamline processes and be able to offer same-day installation without compromising on quality of output.”

Turning to what Roland DG has on offer, with an eye on sustainability, Elvidge pointed to the range of wide-format printer/cutter, specifically the TrueVIS collection. These machines run with TR2 inks, which Elvidge said are especially useful for vehicle wrapping.

“TR2 inks produce vibrant colours across a broad range of applications for extended colour matching capabilities,” Elvidge said. “These inks also provide excellent stretch and deliver durable, long lasting results. They are also available in orange and green to further increase colour gamut. The ink’s fast drying speeds also allow professionals to print and laminate in as little as six hours.”

TR2 inks are also Greenguard Gold certified, meaning that they are virtually odourless and do not requires any special ventilation.

Reacting to market demand

Another leading name that offers print hardware solutions for vehicle wraps and graphics is HP. Mike Lewis, channel account manager at HP, said as vehicle wrapping is such a visual market, printers in this sector face a great amount of pressure in ensuring the final product looks the part.

“Under-investment in print technology could risk you falling short of quality standards and mean you have to reprint the entire piece, costing you time, money and potentially repeat business.

“Accuracy is of paramount importance when it comes to printing wraps, so you need to make sure any print technology that you are investing in is up to the task of hitting these levels of accuracy.

“Vehicle graphics are subject to significantly more stress than other types of printed work, facing both weather elements on an almost constant basis and the strain of remaining in place while moving at speeds”

Lewis said this point also rings true when it comes environmental considerations, as with demand for greener and more sustainable work being on the rise in vehicle graphics, print companies need to do all they can to ensure they are delivering environmentally friendly work.

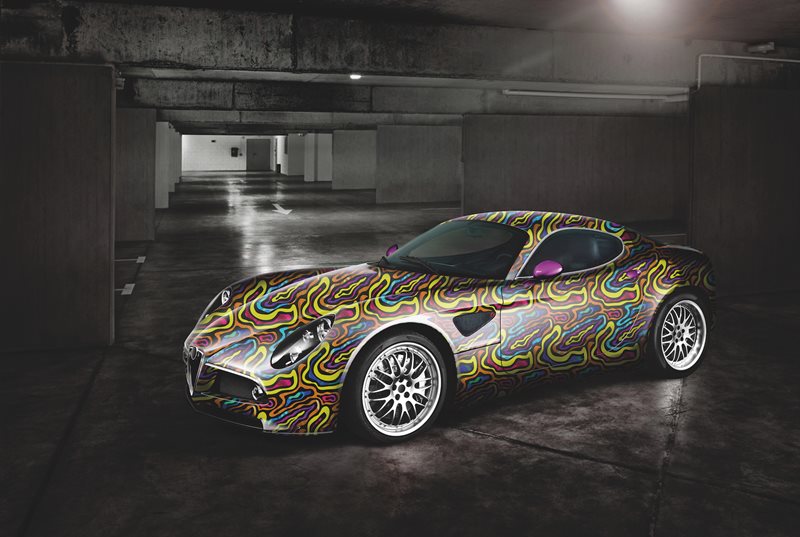

Caption: HP Latex machines can be used to create wraps for vehicle of all shapes and sizes

Caption: HP Latex machines can be used to create wraps for vehicle of all shapes and sizes

“One way of doing this is investing in a greener printer, as then you will be able to showcase to customers your own green approach and how this impacts the environmental credentials of their work,” Lewis said.

With this Lewis, draws attention to HP Latex technology, which he said provides a greener option than solvent equivalents. HP Latex printer use water-based inks and offers print operators a safer working environment, given that there are no HAPs emitted during print.

“It will not change the recyclability of the substrate once printed, so couple latex printing with an eco-conscious substrate and we can reduce the overall environmental impact of a job - a strong message that can be communicated to customers,” Lewis said.

Other advantages of HP Latex printing, Lewis said, include that when printed, wrapping vinyl and films come out dry and are ready to laminate immediately. Outgassing is not required, which cuts production time for printers, meaning the graphics can therefore be printed and applied with a much quicker turnaround.

“We also now have the added benefit of white ink too for creating those extra special effects, with excellent opacity and of course it’s fully formable just like our standard colours,” Lewis said.

“Customers can also choose to invest in a wide variety of platforms to produce their graphics - from 1.3m print width to 3.2m and even hybrid or direct to substrate technology too.”

Future proof your business

Next up, Tom Owers, product manager at Epson, said big brands are demanding that their suppliers show evidence of their proactive approach to CSR, so print companies must look to go green wherever possible.

“Even if you don’t work for big brands now, you should future proof your business by taking action today,” Owers said. “One way to do this is to partner with a company like Epson that has a clear and transparent CSR policy that is easy to communicate.

“Among the options are choosing a system with lower ink consumption, printing onto uncoated stock that can be recycled - dependent on model - and working with a supplier that supports a national cartridge recycling scheme.

“We also supply high capacity inks: R5000 and S80600L in 1.5L or the R5000L 3L bulk ink system that reduce waste from plastic by around 80%, as ink is delivered in foil ink bags instead of plastic cartridges.”

Caption: Epson said as big brands demand that their suppliers show evidence of their proactive approach to CSR, print companies must adapt

Turning to hardware and Owers recommended the eco-solvent Epson SureColour SC-S80600, which he said offers the widest colour gamut in the industry and is thus ideal for hitting specific brand colours.

“It ensures high quality with superb colours and clarity from latest generation dual Epson PrecisionCore TFP printheads and new formulation Epson UltraChrome GS3 with Red inks,” he said. “Unrivalled accuracy is supported by a sophisticated substrate handling system for class-leading performance.”

Meanwhile, Owers said the new SureColor SC-R5000 addresses the existing challenges of working with resin-based inks. The 64-inch printer offers what he described as “exceptional” print performance and colour control, thanks to the PrecisionCore Micro TFP printhead.

Precise temperature control, which is monitored by four temperature sensors, ensures colour is consistent from edge to edge and top to bottom, while three independent heating stations ensure colour uniformity and adept media handling.

“The efficient drying and curing process enables lamination and same-day delivery so users can reduce turnaround times,” Owers said.

With demand for more environmentally friendly products across all areas of the industry on the rise, printers have little choice but to look at how they can go greener. In the vehicle wrapping market, one of the most effective ways of doing this is by investing in a more eco-friendly printer, and by going from what some of the leading manufacturers have said here, there is plenty of choice out there!